Why are cymbals so expensive?

My son recently cracked one of his symbols. This was always going to happen, but financially the timing couldn’t be worse. This started us down the usual pre-purchase Google rabbit hole, and after getting over the shock associated with the cost of a replacement, thought what we learnt might be of interest to others.

Cymbal making involves a lot of skill, time, and research. At each stage of the manufacturing and distribution process, companies need to make a profit, and of course pay their skilled workers. Labour is the primary contributor to the final cost of new cymbals. The cost of raw materials - bronze to be specific - is quite low, at between $4 to $7 per 1kg. While there are cheap cymbals on the market, it can often prove to be a false economy. For more advanced drummers - even children - it is often worth paying a bit more (or a lot more) to get the exact sound you are after. If you are happy to go second-hand, there are many good bargains to be had on ebay. Cymbals depreciate faster than any other instrument or component, and that is for good reason - they cop a beating (literally).

It is impossible to understand why cymbals are so expensive, without deep diving into the materials used to manufacture them, and into the manufacturing process itself. Strap yourself in - this may get detailed.

Broken Cymbal

What are cymbals made out of?

Cymbals are made from some variety of copper alloys. An alloy (for the kids reading this) is simply a mix of metals. Cymbal makers use copper because it is both very malleable (shapeable), and because it naturally sounds great. The malleability of copper is really important, and if you look deep into the history of cymbal production - cymbal makers were able to use very simple tools 3000 - 4000 years ago, to make a similar sounding instrument to what we use today.

The most common copper alloys used in cymbals are what are known as bronzes. Bronze is simply a mix of copper and tin. The most common bronze used in the manufacture of higher end cymbals is an 80 percent copper, 20 percent tin mix, and common rule in cymbal manufacturing is that the higher the tin-to-copper ratio, the more expensive the cymbal (though this does not always hold true). Another generalization is that cymbals with more tin produce a warmer, lower-pitched sound, compared to those with less tin, which typically will have a brighter sound. The 80:20 ratio is quite difficult to work with and requires extensive reworking and re-heating due to its natural brittle state - this obviously contributes to the higher price tag.

The bronze itself is very inexpensive - at approximately USD $4-7 per kilogram. Even if we take the higher end of USD $7, the average raw material cost per cymbal type can then easily be calculated as per the below table. This table lists some common ride cymbal sizes, as these are typically the most expensive cymbals drummers will invest in.

| Cymbal Size | Thickness | Weight in Grams | Raw Material Cost |

|---|---|---|---|

| 22 inch | Extra Light | 2100 | 14.7 |

| Light | 2300 | 16.1 | |

| Medium Light | 2500 | 17.5 | |

| Medium | 2800 | 19.6 | |

| Heavy | 3500 | 24.5 | |

| 21 Inch | Extra Light | 1822 | 12.754 |

| Light | 1996 | 13.972 | |

| Medium Light | 2170 | 15.19 | |

| Medium | 2430 | 17.01 | |

| Heavy | 3037 | 21.259 | |

| 20 Inch | Extra Light | 1735 | 12.145 |

| Light | 1900 | 13.3 | |

| Medium Light | 2066 | 14.462 | |

| Medium | 2314 | 16.198 | |

| Heavy | 2892 | 20.244 | |

| 19 Inch | Extra Light | 1650 | 11.55 |

| Light | 1803 | 12.621 | |

| Medium Light | 1963 | 13.741 | |

| Medium | 2198 | 15.386 | |

| Heavy | 2748 | 19.236 |

How Are Cymbals Made?

Manufacturers will vary, but in general terms there are two ways to make cymbals. Either by pressing huge sheets of alloy into the shape of cymbals, or a longer 10 stages individual moulding process. Each option requires skilled craftsmen and women, a stack of research, and a touch of OCD, and for the average ear - or the partially deaf one - today’s pressed cymbals are subjectively as good as their hand-made peers. In fact, a number of hard rock drummers are preferring the sheet shaped cymbals, as they tend to produce a louder sound.

Cymbal Love

The traditional process is far more interesting, and much more labour intensive - which is why the prices tend to also be higher. It can typically be divided into three main sections: casting, hammering and finishing. The casting alone has four separate processes, and requires a lengthy series of melting, moulding, and re-heating. This is a delicate process, as the above described temperament of the 80:20 bronze alloy, makes this notably more complex.

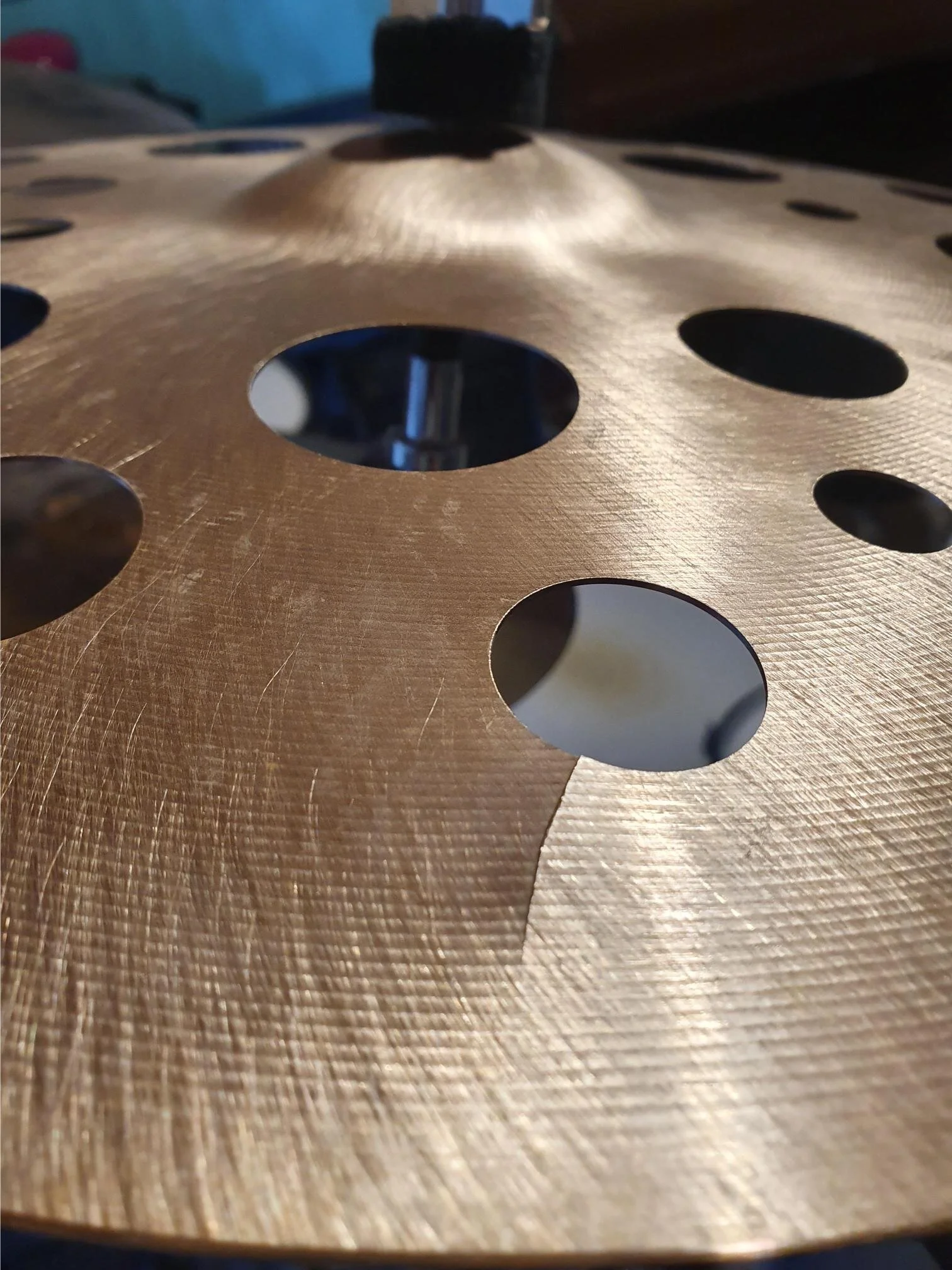

After casting the cymbals get hammered (sorry that sounded better in my head). The hammering is without doubt the most important part of making a cymbal, and there are many variables that will ultimately determine the final sound properties of the Cymbal. For example, the size of the hammer, the number of strikes, or even the way the hammer strikes the surface of a moulded cymbal, will change the shape and thus the acoustic properties. Hammering is an art form, and while modern machine driven techniques have provided a great deal of consistency, this process still requires a skilled, and passionate workforce.

The final stage of cymbal manufacture is the finishing. Now again, depending on the cymbal or sound you are after, there are lots of different ways to finish a cymbal. In fact we plan to write an article on this specifically. Typically though, cymbals are lathed down, smoothed, and then polished. The manufacturer then slaps a logo on, and ships the finished product out.

End to end, the manufacture of a cymbal using traditional methods takes about 1 week. That is a lot of ppl and machinery costs. Modern manufacturing methods, or sheet metal stamped cymbals are typically produced in a day, thus costing less in terms of labour costs. That doesn’t always mean that sheet stamped cymbals are cheaper though…

What’s wrong with Cheap Cymbals

Based on the above, namely the type of alloys used, cheap cymbals are prone to cracking, tearing, and quickly start to sound like trash can lids. Expensive cymbals are typically stronger - even if thinner - and they last much longer than your cheap cymbals. The way cymbals are manufactured typically does not impact this, although you will hear of drummers holding on to their custom hand moulded cymbals for ever!

So Why are Cymbals so expensive?

To summarise, the cost of cymbals has little to do with the raw material. In the case of hand moulded cymbals, the cost of labour is typically what drives the price skyward. For sheet stamped cymbals, there is still an element of skilled labour cost, but the real cost largely comes into the research, machinery, and distribution.

So what decision did we make? To be honest we are still looking, but my son is leaning towards a hand moulded china. Will keep you posted.